What Are You Looking For?

What Are You Looking For?

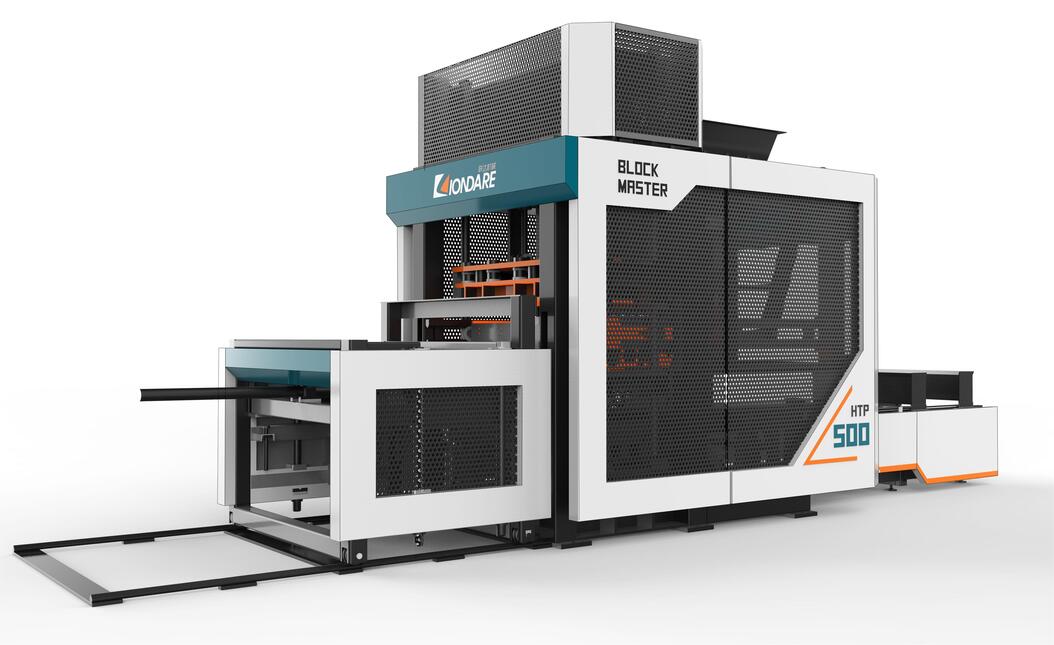

HTP500-6 Intelligent Cement Brick Machine is an ideal choice for construction companies seeking to enhance their productivity and output while maintaining the highest quality standards of cement brick,hollow block and interlock pavement brick etc.

Item No :

HTP500-6Order(MOQ) :

1 SetPayment :

T/T,L/C and Western UnionProduct Origin :

Quanzhou,ChinaColor :

Green &OrangeShipping Port :

Xiamen,FujianDelivery Time :

30-120 DaysGuarantee Period :

1 Year

HTP500-6 Intelligent Cement Brick Machine, Experience the ultimate in automated brickmaking technology with the HTP500-6 Intelligent Cement Brick Machine. Designed to meet the needs of modern construction projects, this cutting-edge machine combines exceptional functionality with unparalleled efficiency. this machine guarantees consistent quality and uniformity in every single brick. Whether you're working on residential, commercial, or industrial projects, this advanced brick machine is the perfect choice.

Specification:

|

Technology parameter: |

|

|

Capacity per stroke: |

35pcs (Holland Brick: 200x100x60mm) |

|

58pcs (Solid Brick: 238*48*113mm) |

|

|

72pcs (Small brick:198*98*44mm) |

|

|

10pcs (Hollow block:400x200x200mm) |

|

|

12pcs (Hollow block:400x150x200mm) |

|

|

12pcs (Pavement brick:250*250*60mm) |

|

|

15pcs (Pavement brick:300*150*50mm) |

|

|

6pcs (Pavement brick:500*250*60mm) |

|

|

Forming time |

15-20(S) |

|

Pallet size: |

1120*880*25mm |

|

Vibration force: |

40KN |

|

Vibration motor power: |

11KW*2 SERVO MOTOR |

|

Frequency convertor |

30Kw |

|

Outsize:mm |

8000×4000×3100mm |

|

Machine weight:(Ton) |

10.5T |

|

Belt conveyor motor: |

3KW |

|

Brick receiver motor: |

1.5KW-1:2P |

|

Bogie hydraulic motor: |

BLINCE 160 |

|

Frequency converter |

Sine |

|

PLC |

Vigor |

|

Touch screen |

Taiwan Vigor |

|

Button |

Schneider |

|

Contactor |

Schneider |

|

Thermal relay |

Schneider |

|

Intermediate relay |

Schneider |

|

Proximity relay |

Turk |

|

Crossing switch |

Taiwan Vigor |

|

Oil pump |

Taiwan |

|

Hydraulic station weight |

690KG |

|

Main machine weight |

8190KG |

|

Pallet sender weight |

300KG |

|

Brick receiver weight |

300KG |

|

Color feeder weight |

1435KG |

Feature:

1. Precision Engineering: Crafted using state-of-the-art precision engineering techniques, HTP500-6 Intelligent Cement Brick Machine ensures unparalleled accuracy in brick production. Each and every brick is meticulously manufactured to perfection, guaranteeing exceptional quality and consistency.

2. Intelligent Automation: Say goodbye to manual labor and embrace the future of brick manufacturing with HTP500-6 Intelligent Cement Brick Machine. Equipped with intelligent automation capabilities, this machine streamlines the entire production process, from material feeding to brick shaping and stacking. Boost productivity, minimize human error, and enjoy seamless operation.

3. Versatility: HTP500-6 Intelligent Cement Brick Machine is designed to adapt to various construction needs. Whether you require standard-sized bricks or customized shapes and sizes, this machine delivers exceptional versatility. It effortlessly accommodates different molds and allows for quick adjustments, ensuring your project specifications are met efficiently.

4. Eco-Friendly Performance: As an environmentally conscious solution, HTP500-6 Intelligent Cement Brick Machine prioritizes sustainability without compromising on performance. With its energy-efficient design and optimized resource utilization, this machine significantly reduces waste, energy consumption, and emissions. Join the movement towards greener construction practices.

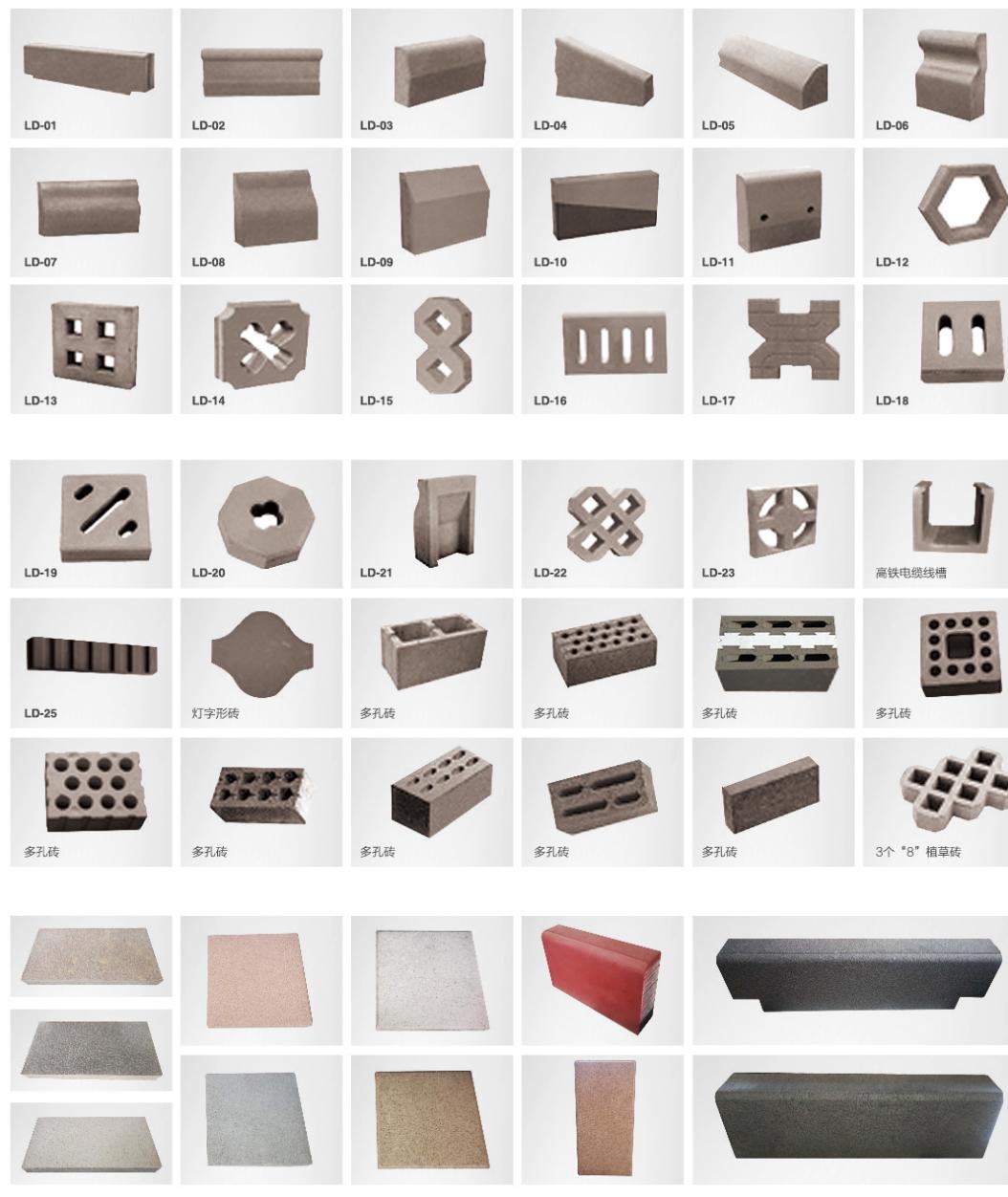

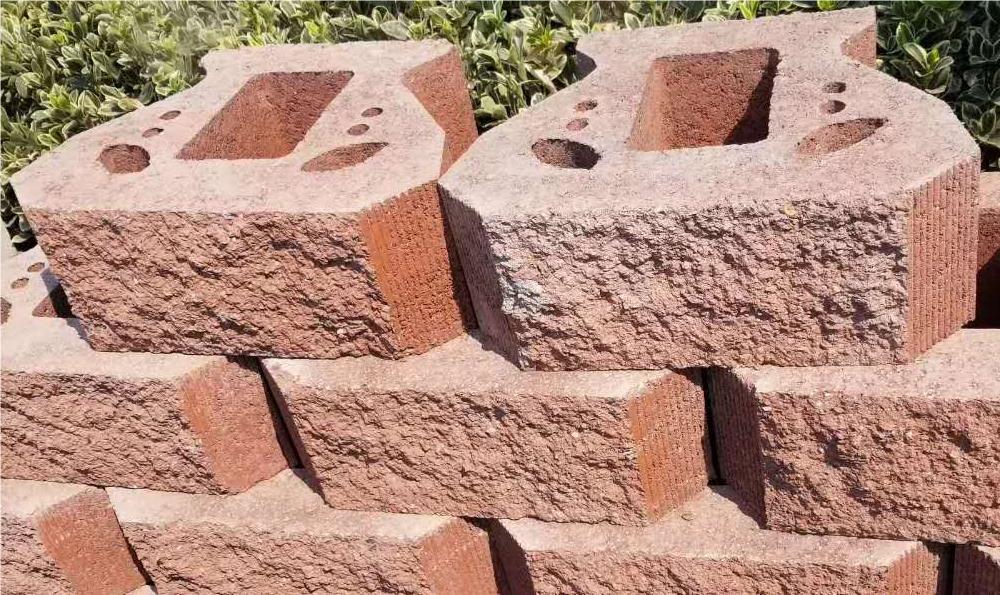

Block samples:

HTP500-6 Intelligent Cement Brick Machine can produce various hollow bricks, solid bricks and pavers by changing the mold. The following bricks are common brick types. At the same time, we can customize brick molds for you according to your specific requirements.

Why Choose us:

1.Our company has been nearly 20 years in the field of Intelligent Cement Brick Machine so that we possess the stable and good usable goods. we have been awarded:China Intelligent Manufacturing Pioneer Enterprise and National High-Tech Enterprise.

2.Choose our brick machine to experience the perfect fusion of precision and efficiency. With our commitment to excellence in every aspect of brick manufacturing, we provide you with the tools to elevate your business to new heights. Discover the difference of a truly exceptional brick machine – the choice is yours.

3. We also has our agents in India,Thailand,Malaysia,Middle East and other countries to completely ensure every client to own a high quality after-service when they are using our Intelligent Cement Brick Machine.

Transportation&After Service:

All the machine shall loaded into containers with proper package,especially in PLC boxes

◎Engineers are available to do service abroad

◎Training &Technical instructing lessons shall be provide during installation

◎Video instruction installation is also available if customer have professional technical engineers

◎One year warranty is provided for customer.

FAQ:

Q:What is the working principle of Automatic brick vibrating machine?

At its core, this machine employs a motor-driven vibrating mechanism that imparts controlled vibrations to the bricks during the manufacturing process. This vibration not only enhances the compaction and density of the bricks but also aids in the removal of air bubbles, ensuring superior quality and strength.

Q:What is the function of vibrating motors in Automatic brick vibration machine?

By imparting vibratory motion, these motors play a pivotal role in the compaction of the brick molds, ensuring a more cohesive and homogeneous mixture. This meticulous compaction process not only facilitates the removal of excess air bubbles within the mixture but also aids in the proper alignment of particles, resulting in robust and structurally sound bricks.

Q:What is the function of light sensor in Automatic brick vibration machine?

The light sensor plays a crucial role in the functionality of Automatic brick vibration machine. This innovative and sophisticated feature enables the machine to operate with the utmost precision and efficiency.